BERI.MOD.MAGIC

Programmable

:

Yes

Cable Types

:

HV

Coaxial

Other

Multicore

Cable Geometry

:

Round

Outer Sheath Material

:

Silicone

Rubbery

Pure

PVC

Other

The manual removal of foil or fabric from normal, coaxial, and high voltage cables, or from wire coatings for example, is laborious and time-consuming. When processing a cable, the first step is to strip completely the cable sheath which may not be desirable for subsequent processes. The machine stripping – for example with rotating blades – forbids itself because the danger of micro-injuries on the layers under the foil cannot be reliably avoided.

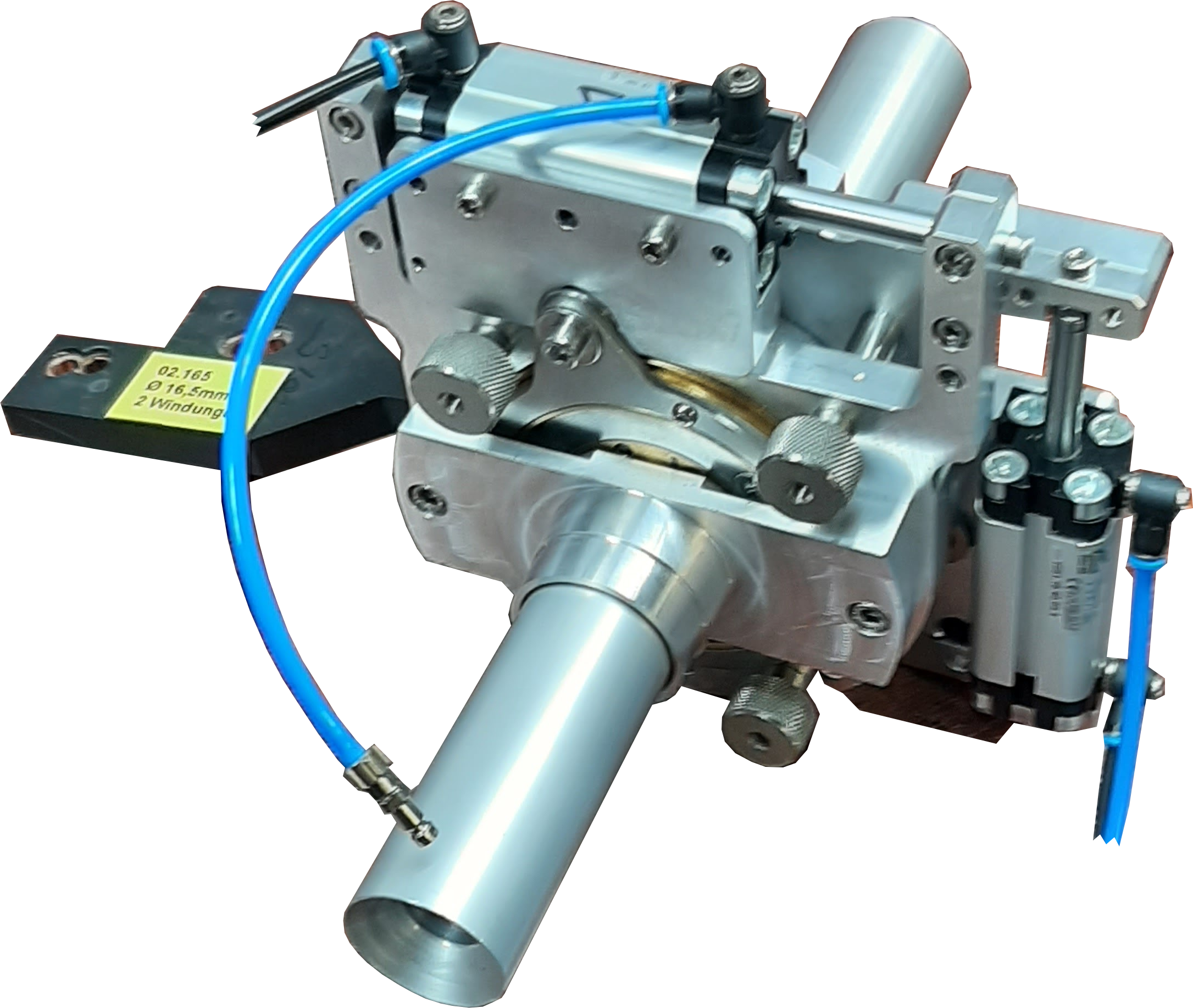

The new thermo-module BERI.MOD.MAGIC for generating warmth by means of an electromagnetic alternating field avoids these disadvantages. It is universally applicable in production lines, or as attachment for current processing machines. The foil-processing-machine BERI.MACH.MAGIC incorporates this thermo-module.

The operating principle is as follows: by heating the metallic parts within hoses, pipes, catheters, wires, cables, or any other bar-shaped and linear mounted materials, the adjacent thermoplastic layers are predamaged through heat transfer. This simplifies the stripping, for example, of foils, fabrics, or any other layered materials during the following processing step.

The operating principles also functions with non-stripped wires.

The new thermo-module BERI.MOD.MAGIC for generating warmth by means of an electromagnetic alternating field avoids these disadvantages. It is universally applicable in production lines, or as attachment for current processing machines. The foil-processing-machine BERI.MACH.MAGIC incorporates this thermo-module.

The operating principle is as follows: by heating the metallic parts within hoses, pipes, catheters, wires, cables, or any other bar-shaped and linear mounted materials, the adjacent thermoplastic layers are predamaged through heat transfer. This simplifies the stripping, for example, of foils, fabrics, or any other layered materials during the following processing step.

The operating principles also functions with non-stripped wires.